Francisco Simplicio made elegant, modernist guitars which were different from those made by his contemporaries. His rosettes, his head carvings and the distinctive bridge decorations set his guitars apart and add to the difficulty in making a true copy. Here is one more aspect that makes his instruments easily recognizable. The linings used on the top and back to the sides are carved to be concave allowing them to support the wide purfling but at the same time to reduce weight.

Tag Archives: flamenco

Simplicio Rosette

Way back in 2004 I visited Casa Luthier and examined a few of the wonderful old guitars they have. I remember a Barbero, Santos Hernández and some lovely guitars made in Catalunya, Spain. One which especially impressed me was a Simplicio and it had this rosette pattern. I never took a photo and I don’t remember the colour scheme but he has used a light pattern on a dark background as well as the opposite so I am happy enough to go with the former and still be true to his spirit.

Way back in 2004 I visited Casa Luthier and examined a few of the wonderful old guitars they have. I remember a Barbero, Santos Hernández and some lovely guitars made in Catalunya, Spain. One which especially impressed me was a Simplicio and it had this rosette pattern. I never took a photo and I don’t remember the colour scheme but he has used a light pattern on a dark background as well as the opposite so I am happy enough to go with the former and still be true to his spirit.

Bridge Update

Mother-of-Pearl

This is the Simplicio copy again and the bridge is just as complicated as the rosette and the headstock. Shaping the pieces of pearl takes time and then positioning them without the inlay in place has its challenges too. We can do all sorts of things with wood but other materials require some study. The mitres at the corners are hard enough to do so I am grateful that he decided to include a strip of wood between the central piece and the frame.

Simplicio

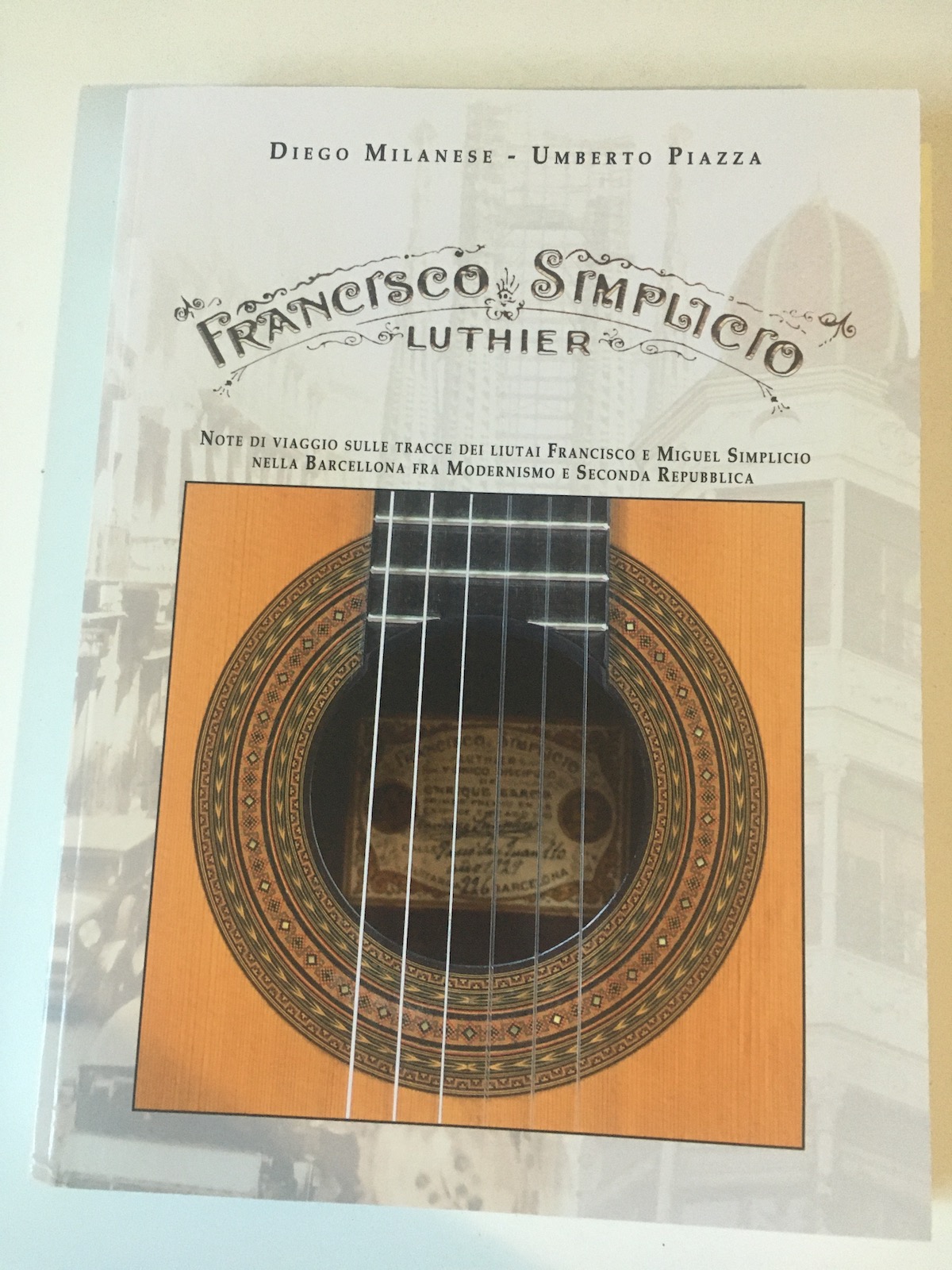

One of the old guitars I got a chance to see this year was a 1928 Francisco Simplicio. I think it was coincidence that at about that time I got an order and the client wanted a copy of Simplicio. Having seen a few of his guitars is not always enough so I enlisted some help. Francisco Jimenez did some careful study of the 1928 and I ordered the Simplicio book from La Stanza della Musica in Rome. I have got a good start on the guitar with the headstock carving done and the rosette and purflings ready to install.