Herman Schamp is another frequent visitor to Granada who fell in love with the city a long time ago. This love is obvious throughout his treatment of the city in black and white photographs. The presentation of his book was on Monday at the Reciclaje bookshop and I ran into a few colleagues there. You see part of Herman’s fascination with Granada are the guitar workshops found in Granada. I know he has learned from some of us, bought guitars from others and enjoyed philosophical and practical conversations. Francisco Manuel Díaz was there, his son Francisco, José Luis Vigil, Alberto Cuéllar, Marcus Toscano and a few other people I know. Marcus played a few pieces on his Sobrinos de Esteso 1974. That reminds me of an idea for a post about the importance of quality in guitar-making.

Tag Archives: nylonstring

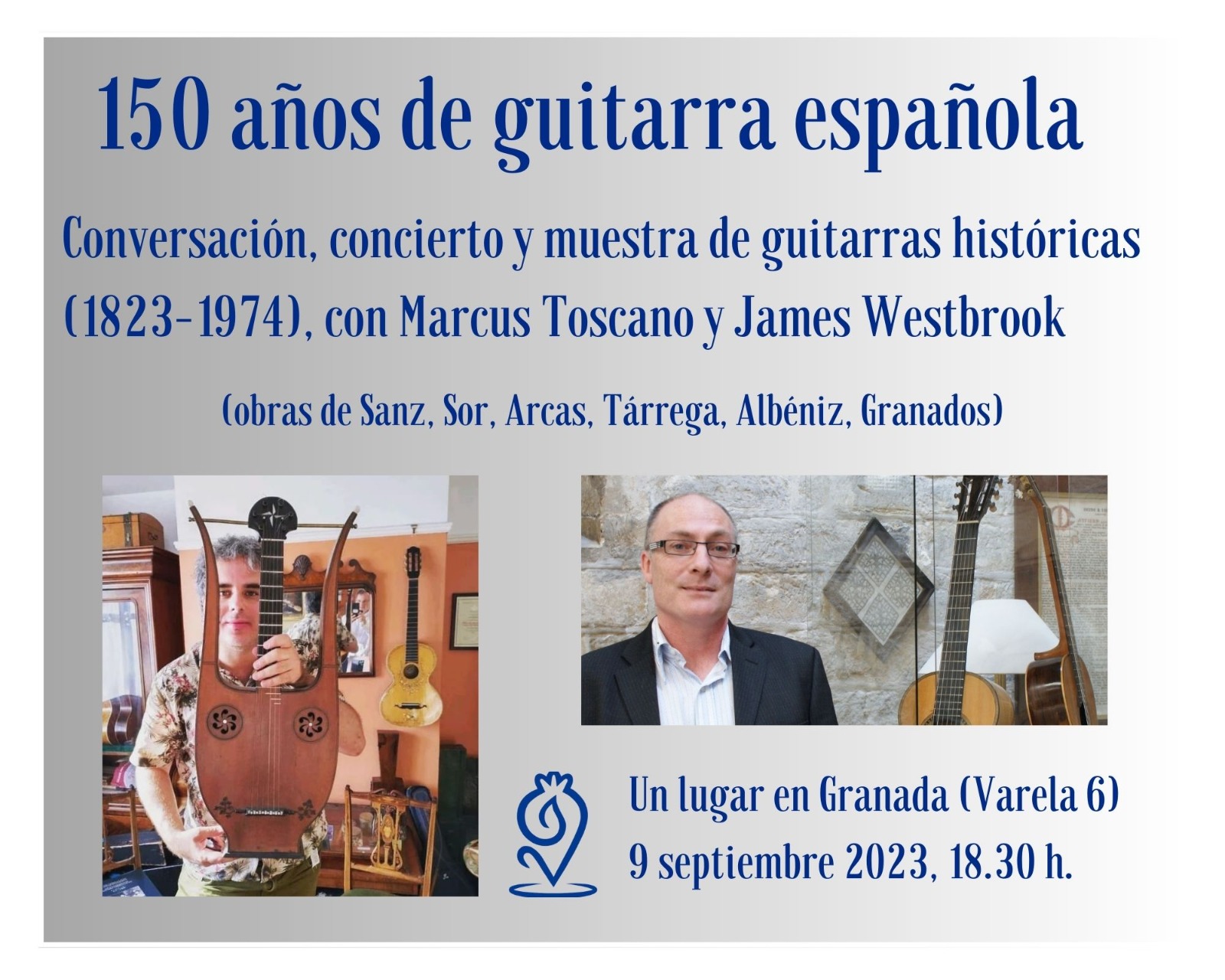

James Westbrook – Marcus Toscano

The Irish Harp

I just got back from a holiday in Ireland. Highly recommended by the way. We had the misfortune to coincide in Dublin with the Aer Lingus College Football Classic so it was overrun with tourists. My son was amazed and very interested in the troubles which we heard all about on our trip to Belfast and Derry. Music was everywhere so of course it made me think of guitars. I often complain that none of the different levels of government here ever do anything to promote the guitar and guitar-makers despite Spain and specifically Granada being the most important centre in the world. Well the Irish do not have that problem. The official symbol of Ireland is the oldest conserved harp in the country (on display at Trinity College). According to our guide Ireland is the only country in the world which uses a musical instrument for its symbol. It just makes me think: Couldn’t we do something like that with the guitar? I suppose Spain could use the bulls, wine, paella, some iconic image of flamenco, a fan, windmills or olive oil but is there anything more universally Spanish than the guitar?

I just got back from a holiday in Ireland. Highly recommended by the way. We had the misfortune to coincide in Dublin with the Aer Lingus College Football Classic so it was overrun with tourists. My son was amazed and very interested in the troubles which we heard all about on our trip to Belfast and Derry. Music was everywhere so of course it made me think of guitars. I often complain that none of the different levels of government here ever do anything to promote the guitar and guitar-makers despite Spain and specifically Granada being the most important centre in the world. Well the Irish do not have that problem. The official symbol of Ireland is the oldest conserved harp in the country (on display at Trinity College). According to our guide Ireland is the only country in the world which uses a musical instrument for its symbol. It just makes me think: Couldn’t we do something like that with the guitar? I suppose Spain could use the bulls, wine, paella, some iconic image of flamenco, a fan, windmills or olive oil but is there anything more universally Spanish than the guitar?

Antonio Marín Montero

This year the guitar festival here in Granada includes an exhibition of photographs taken in the workshop of Antonio Marín. The photographer is Pepe Marín (not a family member). Once again Vicente Coves and the European Guitar Foundation are recognising important figures in the guitar community in Granada. Antonio was part of a change in the quality and professionalism of the guitar-makers in Granada in the 1960s that included others but for a number of different reasons he is the best known of those and any other makers here. The quality of his instruments, the number of guitars he has made and his generosity and sociability have made him what he is today.

The poster for the exhibition is shown here with my friend Marcus Toscano; guitarist and Spanish guitar expert.

Cutting it Close

Nothing out of the ordinary today but I just wanted to illustrate how nicely this worked out. This back had some sapwood which is nice if symmetric but that was not the case. It was very narrow to start with so I had to use it with the sapwood. However, as you can see, I glued the narrow back on with very little margin for error but it worked out perfectly. The binding and purfling will just cover up the sapwood. I have some fantastic wood in my stock but most of it has some kind of detail that will make me have extra work when I use it.